I’ve finally had the time to finish one of my long-running projects repairing GE’s most powerful radio offering from 1937, the GE F-135. I picked it up from Craigslist back in November but other responsibilities kept me from getting much done on it until the 1st of this year. Finally, after a few months waiting, it’s finished and playing!

The radio came to me complete and in decent shape for the age. It’s missing the glass for the dial, but is otherwise completely intact and the finish isn’t in bad shape despite a few scratches here and there.

This radio is the current king of my collection. The best radio GE sold in 1937, it has a lot of innovative features – early APEX hi-fi reception, dual 6L6 output tubes putting out 20W of audio to a large and rich-sounding 12″ speaker; a total of 13 tubes including a tuned RF stage, dual IF stages, separate oscillator and “station seeking” automatic frequency correction.

Under the chassis it’s in decent shape too. It looks like it has been worked on before a few times – there are some ’40s, a ’50s and a couple of ’90s capacitors installed. There’s a sticker from a Seattle-area Jukebox Repair store on the back which probably explains the more-recent repairs; I looked up the address and they don’t seem to be around anymore.

First thing first after doing the complete set of intake checks on the radio, I gave the cabinet a thorough scrubbing and hit it with Howard Restore-a-Finish and it came out beautifully. The intake checks were uneventful so I didn’t take any photos, but the power transformer, all the IF transformers, oscillator and antenna and RF coils and the speaker transformer and coils were just fine. After applying the Howard’s, it really cleaned up the fading and covered over a couple of small scratches and really brought out the natural shine on the wood.

Then I tested all the tubes and found that most were in good shape (especially the 6L6G tubes installed) there were a few 6J5 and 6K7 tubes that needed replaced. I had these in stock and so it was easy to solve that problem.

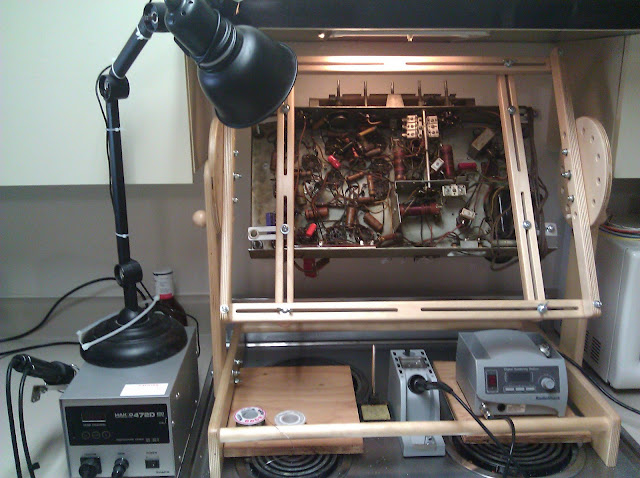

I worked on this one under my kitchen’s vent hood as it’s currently too cold to vent soldering fumes outside. The chassis stand is the right width though so that’s perfect.

Every paper and filter capacitor needed replaced, as well as nearly every single one of the resistors which had drifted as much as +100% in value in some cases. Fortunately the coils are all intact or this could’ve been a much messier repair.

I also found a couple of places where the previous repairman who worked on the set may have been dyslexic, as there were a couple places were numbered resistors were reversed – i.e. R23 being in R32’s place and so forth. I imagine that couldn’t have made it work any better, anyway. I tested and replaced going along from the bottom up as needed. These are in-progress shots, so you might see a couple places where leads aren’t trimmed or components aren’t yet soldered. All of those issues were taken care of but might not have made it into the photo series.

Small caps dealt with, it was time to replace the multi-section caps. There is a 4-section can, insulated from the chassis, mounted up top with a set of 2 filter caps and 2 cathode-bypass caps. These all ran to a hole in the chassis where they went above. I snipped the long cross-chassis leads and moved the components close to their intended locations. In this photo, I’ve replaced the 10uF cathode bypass capacitor with its replacement. I like using bipolar caps for the large-value cathode bypasses but that’s just my preference and what I keep in stock (I keep those values around for repairing crossovers in old speakers) but you could use a standard polarized capacitor there.

Here’s the totally-complete underside shot.

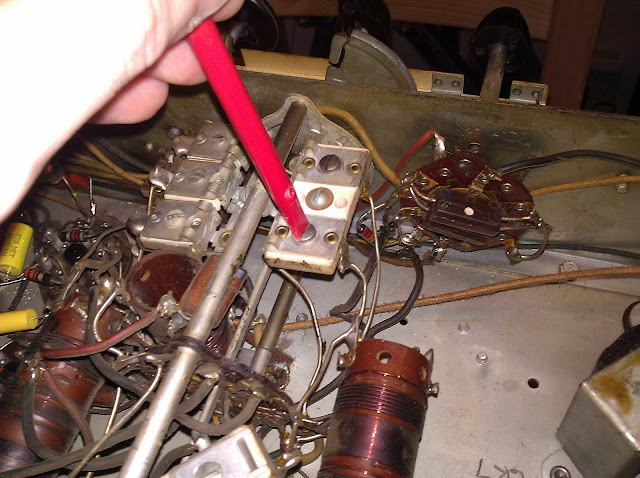

There’s still a matter to deal with above the chassis, though. This is an AFC radio which uses a special and complicated transformer heading into the diode which recovers the audio. And it has a small resistor which is reading double it’s value and needs replaced as well, or it won’t align right.

Then I sealed the can back up:

I hooked the speaker and pushbutton assembly up on the bench and gave it a test run – it fired up immediately and started pulling in a few stations even on the Shortwave bands. The dial was off alignment a bit though, so it was time for that.

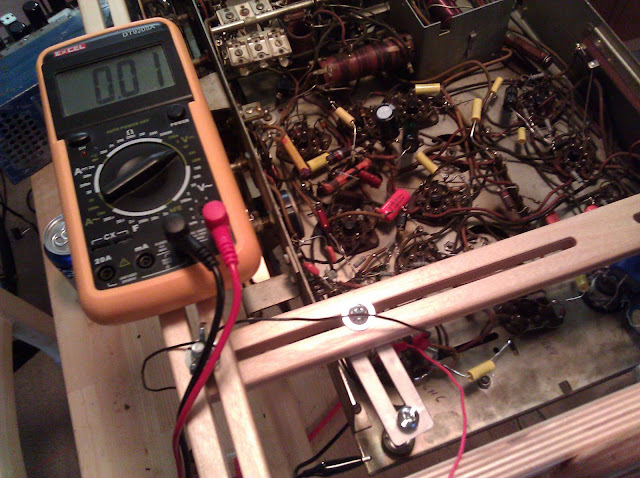

For the alignment, I pulled up the signal generator and started with an IF alignment before going back to the RF stages. This radio has a special IF arrangement with a procedure, so I aligned the 3rd IF primary, second IF secondary and primary, first IF secondary and primary, then went back and aligned the 3rd IF secondary that feeds into the diode. Aligning that discriminator was a maddening 10 minutes spent trying to nudge the adjustment ever so slightly. My goal was to get 0V between two segments, but it approached that point at an incredibly steep slope. I managed to get it there, though.

The original 0V spec was made with a primitive meter; I’ll take 0.01 on a more sensitive modern instrument. That’s perfect IF alignment. It was definitely worth it though. Now onto the RF, which involved tweaking something like 16 trimmers in a precise order with an RF signal generator at various frequencies.

Finally, it was all set! Time to reassemble.

At this point, the radio plays beautifully and pulls in stations from all over, and I’ve added a line input to let me hook up an audio source. The hassle of the AFC calibration was definitely worth it, it’s nearly like magic to watch it work. With the switch off, the radio tunes sharply and a station comes in over just a few degrees of rotation. With the switch activated, it’s like an entirely different radio – the same station will come in across about a quarter-turn of the knob, 2 divisions in either direction from the center frequency and it will block quieter stations from interfering.

The radio sounds great with a pretty good frequency response and more volume than I know what to do with, too. The relay for the motor is burnt out, though. I missed that on the initial checks so when I went to test the pushbutton function…I got a whole lot of nothing. I’ll make another post here when I do get the motor resolved but for now I’m going to hang this one up and start playing it. This was a very fun and enjoyable project and I have a beautiful radio with a commanding presence to enjoy for many years to come.